Ship in a Bottle Assembly of Linked Functional Microdevices

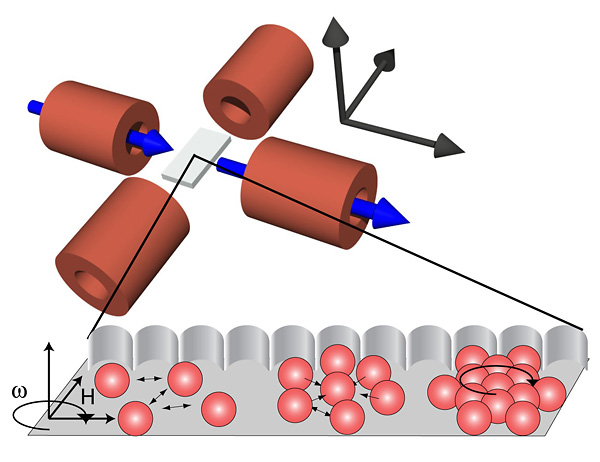

With the external rotating magnetic field causing attraction between single paramagnetic particles and exerting a torque on clusters of colloids, we are able to in-situ assemble moving parts of microfluidic devices in confining geometries out of 4.5µm sized colloidal particles as building blocks. This enables us to build up complex cluster geometries at spots that would be inaccessible to single, compact objects with comparable shape, similar to the construction of a Ship-in-a-Bottle (picture 2). Once assembled, the devices can be powered non-invasively by external magnetic fields in a highly parallel way. With these tools in hand, we realized several microfluidic pumps, valves and mixers.

Movie 1: Simple pump

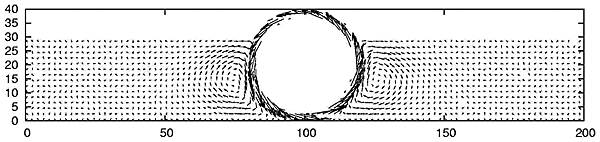

Movie 1 shows a simple pump realized by a symmetric, rotating cluster of 7 identical, paramagnetic colloidal particles. Due to the resistance of the surrounding liquid, the symmetric shape of the cluster is preferred i.e. the pump is self-assembling (see movie 2). The break of channel symmetry by the cavity the cluster is sitting in causes a net pumping effect at the order of nl/h. Simulation data of the flows created is shown in picture 3.

Movie 2: Self Assembly of the symmetric cluster of 7 particles

Movie 3: Realization of a check valve

Movie 3 shows the realization of a check valve by 7 paramagnetic particles in a confining geometry. Flow is allowed from left to right in this picture, whereas flows from right to left are blocked due to a clogging of the only outlet by the rotating cluster.

Movie 4: Miniaturized piston pump

Movie 4 shows a miniaturized piston pump 2.5 times accelerated. This microfluidic device is realized by three active parts that only in combination fulfill the desired function. The pump consists of a ‘piston’ that is created by an assembly of 13 paramagnetic particles in shape of a cogwheel that couples, in a rack-and-pinion arrangement, pinion rotation to translation along the teeth of the complementary rack. The general idea is illustrated in picture 4 where a rotation of a square ‘wheel’ leads to a smooth translation along a ‘road’ composed of a series of truncated catenaries where y = -cosh(x) and the angel at which these catenaries meet corresponds to the interior angle of the square wheel

When the cogwheel reaches the end of the road, rotation of the magnetic field is flipped and the cluster also reverses its direction. Since an arrangement like this would only move fluid back and forth, additional devices to rectify the flow is required for the realization of a working pump. This is done by two compounds of 10 colloids with diamond shape that, depending on the direction of the rotating magnetic field, block one of the outlets and therefore only allow flow from top to the bottom of the total structure in movie 3.

Aside from the realization of a more complex and more powerful pumping mechanism than the one in movie 1, this device also demonstrates the versatility of our approach: With the global magnetic fields we are not only able to assemble and power in principle hundreds of micro devices parallel and non-invasive, but also to run hundreds of different devices independent of each other. Exemplary this pump demonstrates that different assemblies out of the same building blocks in the same magnetic field independently can perform completely different functions, each only defined by the geometries of the cluster and the surrounding confinement. The ability to actuate many single units parallel with only one external power source finally offers great potential for future Lab-on-a-Chip applications with highly complex architectures with networks of independent devices.

Movie 5: Mixing chamber

Water in channels with diameters at the order of tens of micrometers exhibits quite different behavior than water we all know in our daily life in the macroscopic world. At these length scales, viscous forces dominate inertia forces (low Reynolds Number) i.e. water behaves like a very viscous fluid. This has quite dramatic effects on the movement in liquids at the microscopic level, e.g. bacteria have to apply special strategies to be able to move at all. Especially the mixing of two fluids can not be achieved only by stirring, since reversing of the direction of stirring would de-mix the two fluids again (time-reversibility of the Stokes Equation). The only mechanism to irreversibly mix fluids is given by the diffusion of fluid molecules, ions or particles, which, depending on the involved length scales, can take a lot of time. Therefore, for the realization of an effective microscale mixer one has to apply strategies to ‘assist’ the process of diffusion.

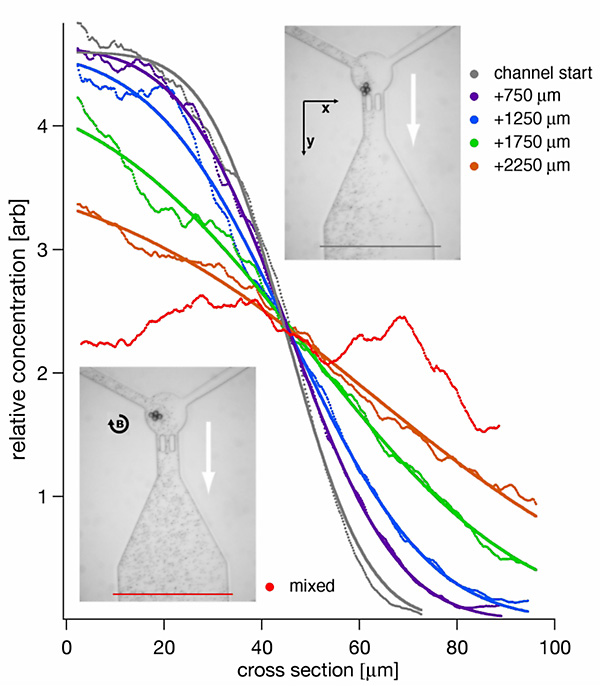

Movie 5 shows a mixing chamber in 4 times the real time. Two fluids (in this case clear water and water with tracer particles) are flowing into the mixing chamber from the right hand side. First the movie shows the mixing chamber with running stirrer, creating a homogeneous tracer particle distribution in the outlet channel. In the middle of the movie the rotation of the cluster is stopped, leading to the development of a interface between the two fluids, where the laminar flow regime can nicely be observed.

To effectively mix, the stirring cluster of 4 paramagnetic particles is rolling up the interface between the two fluids, enlarging the interface by a multiple and therefore assisting the mixing by diffusion. To be able to compare the effectiveness of mixing related to pure diffusion, tracer particle distribution was measured at different positions down the outlet (picture 5). One can see that, with a rotating cluster the particle density taken directly after the mixing chamber (red) is more homogeneous than after 2250µm (approx. 10min) of pure diffusion without rotation of the mixing cluster (orange). Of course, the tracer particles in this case only represent an extremely slow diffusing liquid, real molecules of liquids would diffuse by orders of magnitude faster and therefore mix even more efficiently.

The shown examples represent a full set of simple devices that are capable of performing the basic operations of Lab-on-a-Chip applications, pumping, mixing, and valving, availing itself of a new method to build, assemble and power single units using magnetic fields and paramagnetic colloidal particles. Being able to run many devices parallel and independent with only one external, non-invasive source of power, this new approach offers the possibility to realize highly complex networks of microfluidic operations. Though we employ commonly-used soft lithography methods in fabricating the surrounding matrices, our method is, in contrast to other techniques, not limited to elastic channel structures and can be applied within other materials such as glass or silicon or fully monolithic design development. In addition, the shown devices are scaleable up or down without principle problems. As it is also possible to miniaturize electronic components like coils to scales applicable with our devices, integration of microfluidic devices onto electronic chips is feasible.